Making the most of your block making machine involves several steps, including:

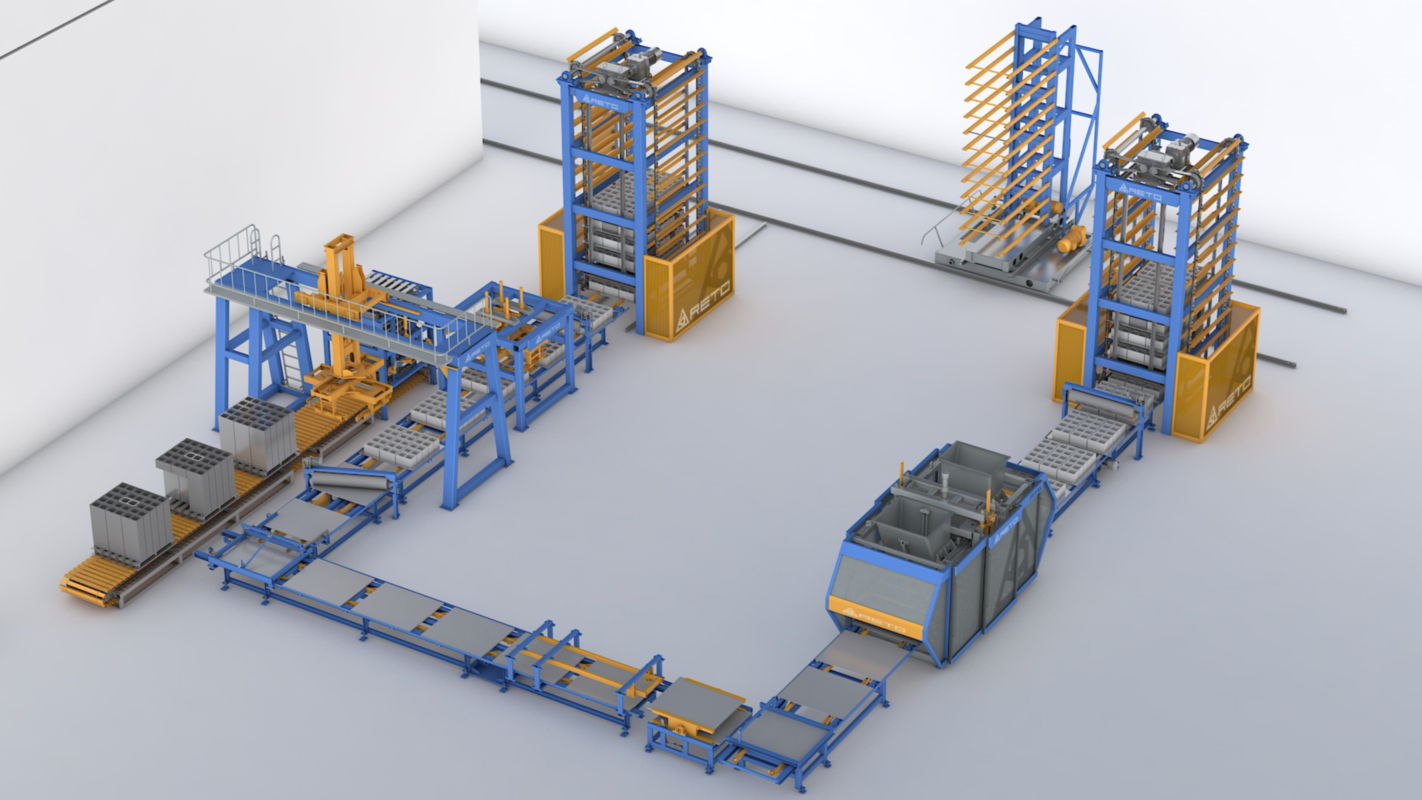

Choosing the right machine: Select a block making machine that is appropriate for the type of blocks you want to produce and the scale of your operation. Consider factors such as production capacity, automation level, and cost-effectiveness.

Maintaining the machine: Proper maintenance of the block making machine is essential to ensure optimal performance and longevity. Follow the manufacturer’s recommended maintenance schedule and keep the machine clean and well-oiled.

Using high-quality materials: Use high-quality raw materials such as cement, sand, and aggregates to produce high-quality blocks. Ensure that the materials are stored properly and are free from contaminants.

Regularly testing the blocks: Regularly test the blocks produced by the machine to ensure that they meet the required quality standards. block making machine Conduct compression tests and other relevant tests to assess the strength and durability of the blocks.

Properly curing the blocks: Properly curing the blocks is essential to ensure that they reach their full strength and durability. Follow the manufacturer’s recommended curing time and conditions.

Developing a marketing strategy: Develop a marketing strategy to effectively sell the blocks produced by the machine. Consider factors such as target market, pricing, and distribution channels.

Continuous improvement: Continuously improve the block making process by identifying areas for improvement and implementing changes. Monitor production efficiency, quality, and customer feedback to identify areas for improvement.

By following these steps, you can make the most of your block making machine and produce high-quality blocks that meet the needs of your customers.

Tips To Make a block making machine Installation Successful

Installing a block making machine can be a complex process that requires careful planning and execution.

Here are some tips to make a block making machine installation successful:

Choose the right location: Choose a location for the block making machine that is level, dry, and has adequate space for the machine and any associated equipment or materials.

Prepare the site: Prepare the site by clearing any obstructions and ensuring that the foundation is stable and capable of supporting the weight of the machine.

Have the necessary tools and equipment: Make sure you have all the necessary tools and equipment on hand for the installation, including lifting equipment, cranes, and power tools.

Follow installation instructions: Follow the manufacturer’s installation instructions carefully to ensure that the machine is installed correctly and safely.

Test the machine: Test the machine thoroughly before putting it into production to ensure that it is functioning properly and that all safety features are working correctly.

Train personnel: Train personnel on how to operate the machine safely and effectively. Provide ongoing training and support to ensure that personnel are knowledgeable and confident in their ability to operate the machine.

Maintain the machine: Proper maintenance of the machine is essential to ensure optimal performance and longevity. Follow the manufacturer’s recommended maintenance schedule and keep the machine clean and well-oiled.

Monitor performance: Monitor the performance of the machine regularly to identify any issues or areas for improvement. Conduct regular inspections and tests to ensure that the machine is functioning properly and producing high-quality blocks.

By following these tips, you can ensure that your block making machine installation is successful and that you are able to produce high-quality blocks efficiently and safely.